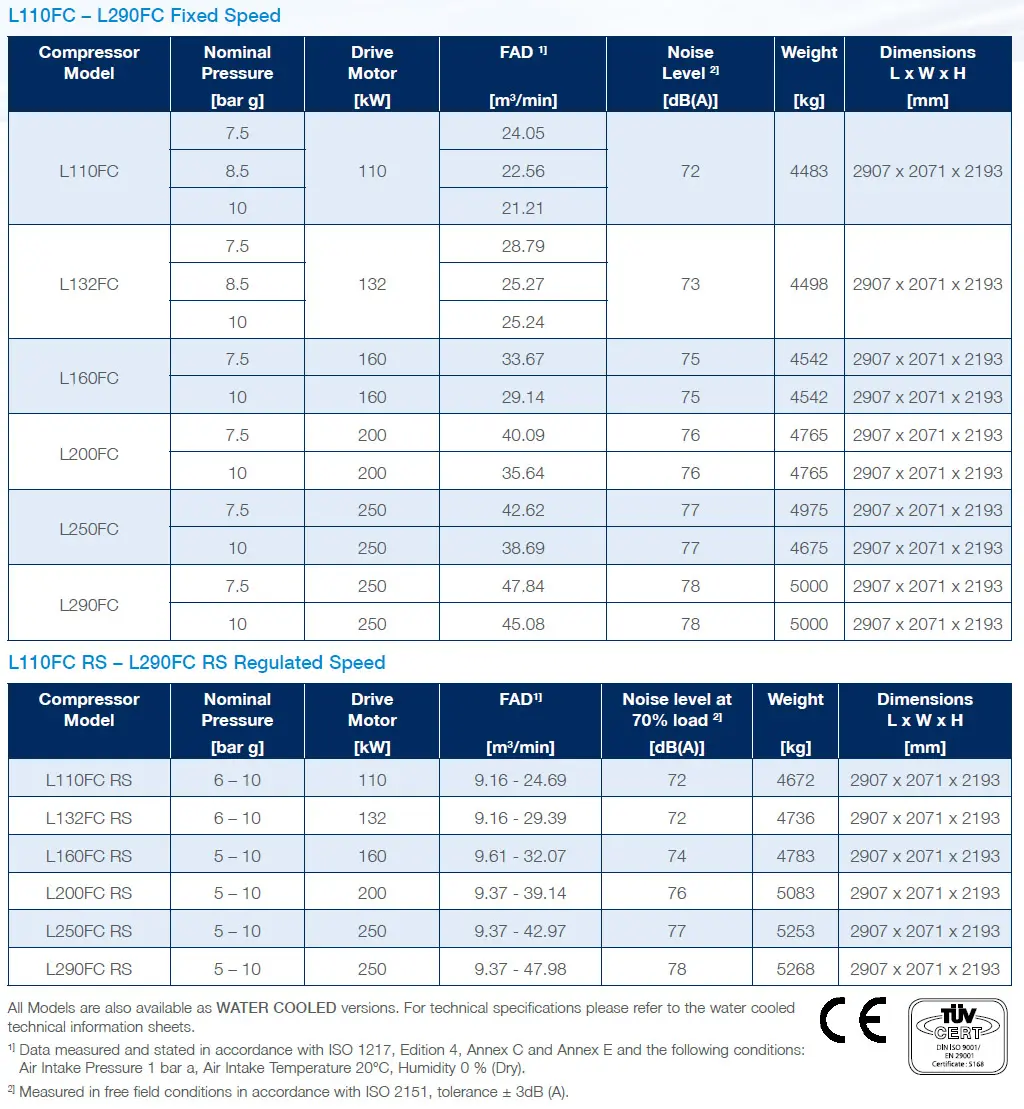

Single and Two-Stage Lubricated Screw Compressors 160 - 250 kW

160 - 250 kW

Fixed & Regulated Speed L160 to L250

By listening to our customer’s needs and wishes, and incorporating the latest technology and design concepts, CompAir has delivered an impressive range of compressors featuring higher free air delivery, new compact footprint, lower noise levels, new split radial cooling fan design, new controller, and many more features besides.

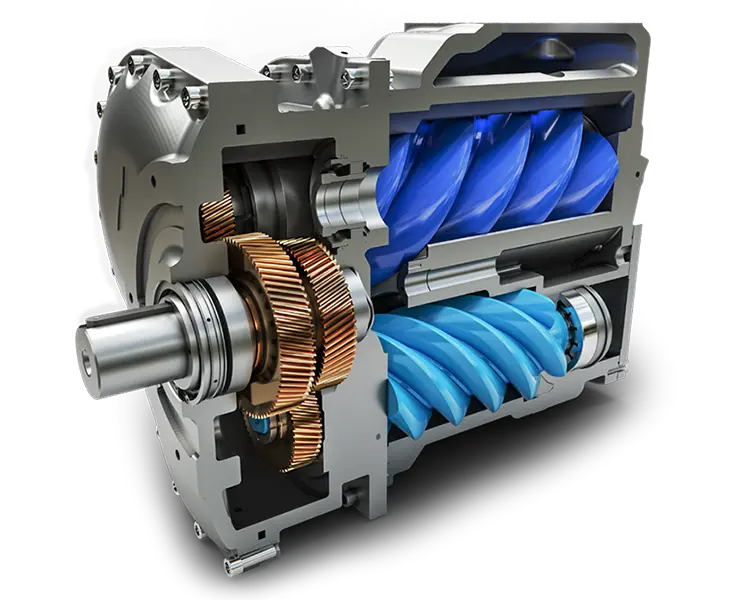

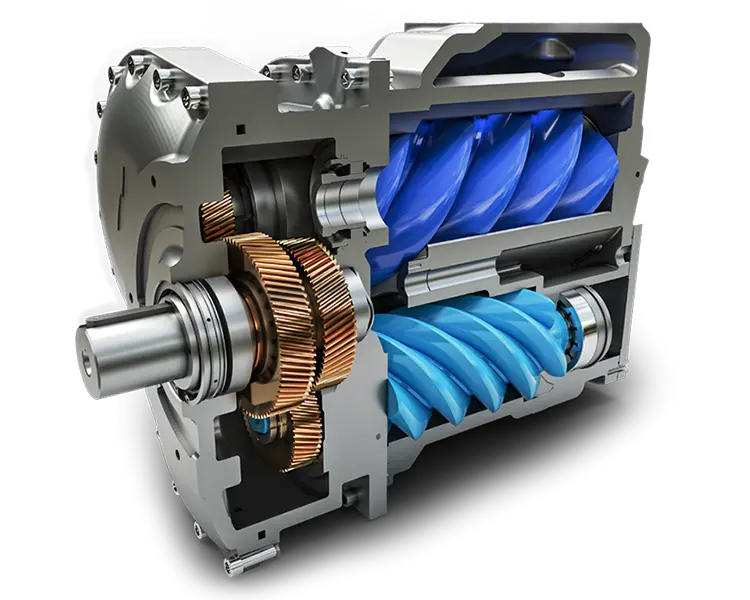

The new FourCore compressor airend

New CompAir FourCore range balances two-stage efficiency with single-stage footprint

CompAir has announced the launch of its new 110 to 250 kW FourCore compressor range, combining best-in-class compressed air efficiency with a small footprint and sustainable design for eco-conscious businesses.

The FourCore range offers all the capabilities of a two-stage compressor, but with only the footprint of a single-stage unit. It therefore provides businesses – who might not have previously had the on-site space available – the opportunity to take advantage of the capabilities of two-stage technology. And when compared with previous single-stage compressors in this size range from CompAir, the new models are up to 8 per cent more efficient, offering a best-in-class oil-lubricated solution for decision makers.

Our application engineering team, based at the Simmern Centre of Excellence production site in Germany has designed and engineered a brand new, patented technology that offers best-in-class energy efficiency. They have developed a premium efficiency 2-stage model for fixed and regulated speed compressors using the new technology of the compact double stage airend. What’s unique about this design is that the airend has 1 motor and 4 rotors located in a single, semi-integrated casting. This differs from traditional 2-stage compressors, providing a compact package with high energy savings. In fact, these machines are the same size as a 1 stage machine due to new airend technology.

Click the design tab above to learn more

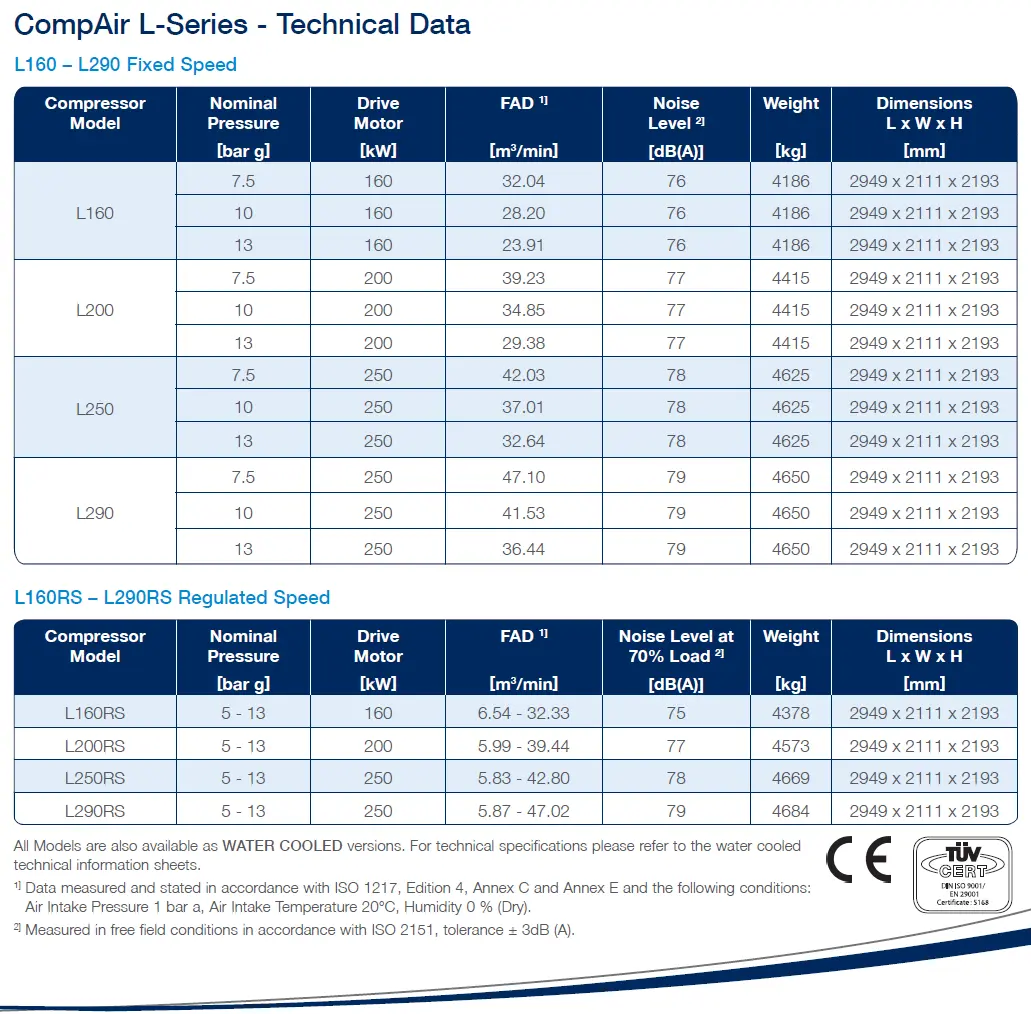

The Classic 160 to 250kW Range

The new E models are offered in addition to the well established existing large screw compressor range which has been offered over many years, with 1000’s of installations worldwide, continuing to power the larger volume air requirements of a diverse range of industries.

How Industry benefits from CompAir:

- Premium airend providing high reliability

- Automatic motor lubrication system for optimum protection

- Low installation costs thanks to the compact design

- High quality air

- Safe and economical operation

- Excellent accessibility contributing to the low maintenance costs

High Speed Lubricated Screw Compressor 160 - 250 kW

With the global rise in electricity prices, the energy costs of compressed air have increased to as much as 91% of the total cost of ownership, and operators need to urgently review the efficiency of their system says Graham Read, Product Manager Industrial Compressors Europe at CompAir, click here to read more.